Operations Inventory Control Delivery

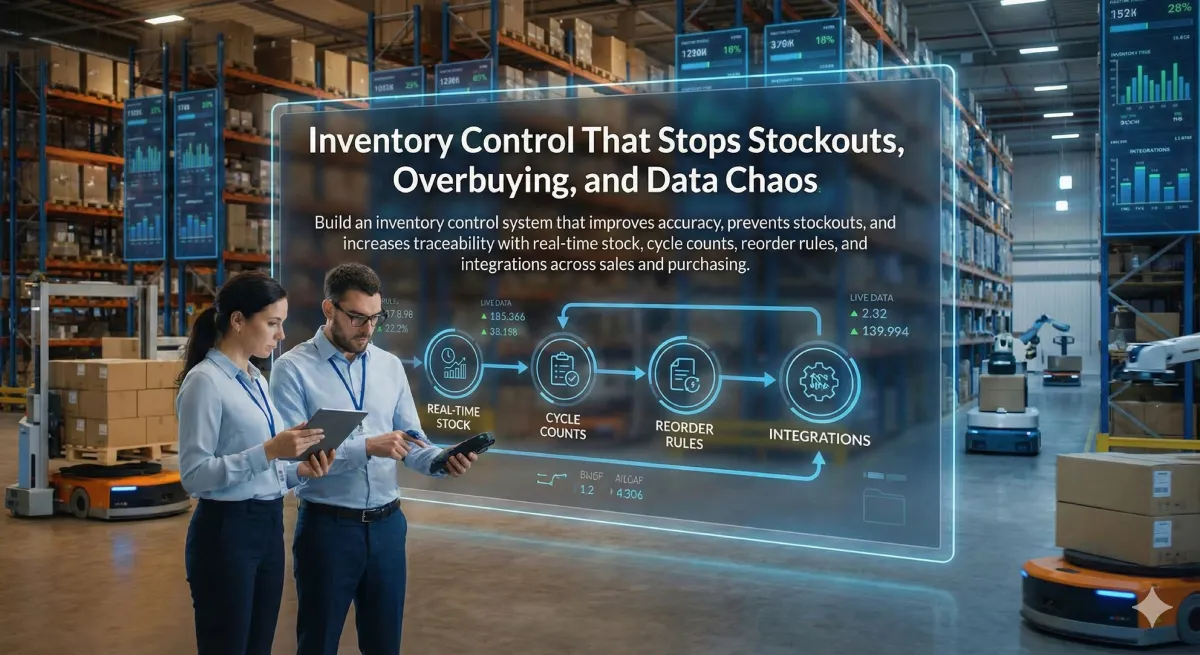

Inventory Control That Stops Stockouts, Overbuying, and Data Chaos.

Move from spreadsheets and manual checks to a reliable inventory control system that gives real-time visibility, tight traceability, and clean handoffs between sales, purchasing, and fulfilment.

- Real-time stock accuracy: live movements, reservations, and availability rules.

- Traceability & control: batches/lots, locations, adjustments, and audit trail.

- Reorder intelligence: min/max, lead times, safety stock, and exception alerts.

- Integration-ready: connects cleanly with sales, procurement, and finance.

Location control

Bins, zones, and movements.

Scanning-ready

Fast receiving & picking.

Lot & batch traceability

Controlled adjustments.

Stockout prevention

Reorder rules & alerts.

Governance

Roles + audit trail.

Inventory Workflows That Stay Accurate Under Pressure

Inventory breaks when the business gets busy. This delivery focuses on the operational reality: controlled movements, fast receiving/picking, and clean rules for what “available” truly means.

Receiving & put-away

Structured receiving, QC status, location assignment, and discrepancy handling—without silent data drift.

Stock movements & adjustments

Internal transfers, consumption, write-offs, and reasons—tracked with a full audit trail and role control.

Reservations & allocations

Prevent overselling by managing reservations for quotes/orders, with configurable allocation rules.

Cycle counting

Rolling counts by zone/category, variance reports, approvals, and controlled corrections.

What Improves in 30–90 Days

The objective is operational confidence: fewer surprises, fewer exceptions, and inventory data that holds up in audits and peak periods.

-

Higher stock accuracy

Controlled movements, approvals, and count discipline.

-

Fewer stockouts and rush orders

Reorder logic based on lead times, safety stock, and demand patterns.

-

Cleaner fulfilment execution

Picking/packing processes aligned to locations and reservations.

-

Audit-ready traceability

Who changed what, when, and why—across critical stock events.

Delivery Package

A controlled inventory foundation your team can own.

You get a maintainable baseline: documented flows, governance, and an integration plan aligned with your operations.

Process mapping: receiving, movements, counting, reservations

Governance: roles, approvals, audit trail, structured logs

Integration plan: sales, purchasing, finance touchpoints

Documentation: onboarding notes + handover checklist

Not sure what’s causing inventory drift?

Request a free architecture review and get a practical roadmap for accuracy, controls, and integrations.

Typical response time: within 24 hours • Clear scope & timeline • Documentation included

Inventory Control FAQ

Decision-grade answers focused on operational fit and delivery risk.

Can this work alongside my current accounting or ERP?

Yes. Inventory control can be delivered as a clean operational layer, integrating stock signals and documents where needed, without forcing a disruptive system replacement.

How do you prevent silent stock changes?

Movements and adjustments run through roles, approvals, reason codes, and audit trail—so every change is accountable and traceable.

Do you support cycle counting and variance reporting?

Yes. Rolling counts by zone/category, variance dashboards, and controlled correction flows are included to keep accuracy stable over time.

What’s a realistic first milestone?

A practical baseline is receiving + movements + availability rules + a basic reorder model—then expand into scanning, traceability, and advanced allocations.