Why “Returns” Become a Profit Leak in Manufacturing

In manufacturing, a return is rarely “just a return”. It touches commercial terms, quality, logistics, stock valuation,

and sometimes warranty obligations. When the process is unstructured, the business pays twice:

once in operational cost (labour, freight, rework) and

again in lost trust (slow responses, inconsistent decisions).

Common failure pattern

“Accept everything, inspect later” creates backlog, stock confusion, and credit disputes.

A real returns and claims workflow controls the decision points upfront.

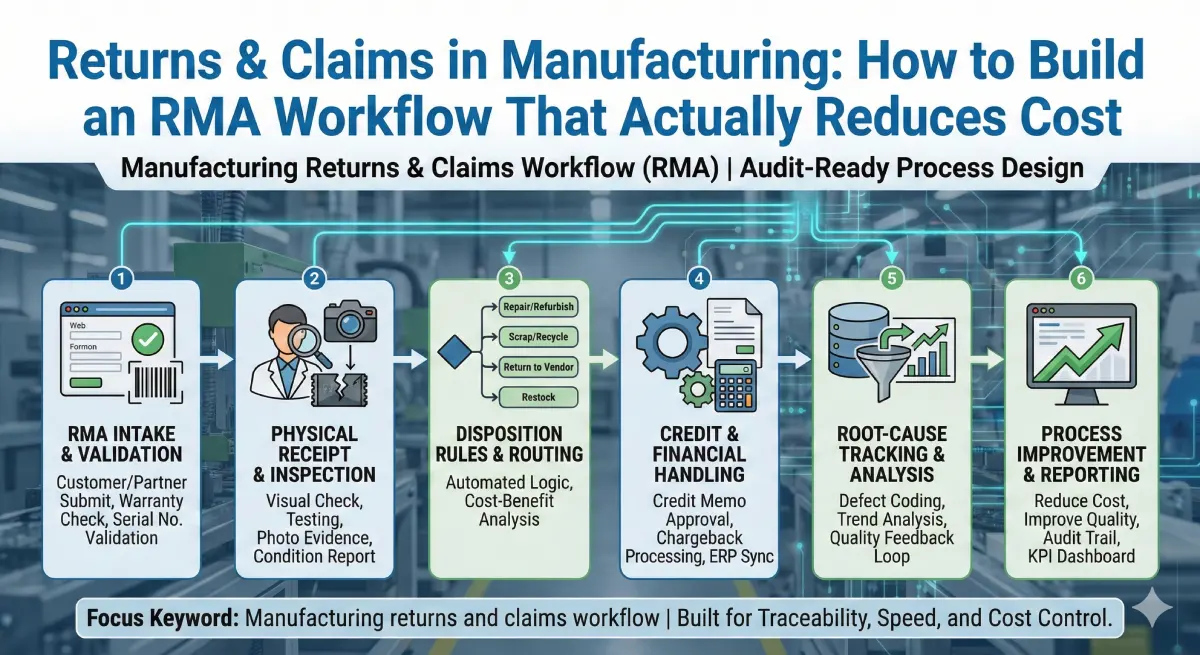

The End-to-End RMA Workflow (What “Good” Looks Like)

A high-performing RMA (returns) workflow is a sequence of gated steps. Each step answers one question:

What is the status, who owns it, and what happens next?

-

1) Claim intake:

capture who is claiming, what item, quantity, evidence, and requested outcome (credit / replacement / repair).

-

2) Eligibility check:

policy validation (warranty window, condition rules, serial/lot traceability, return reason).

-

3) Authorisation:

issue RMA number, routing instructions, and required packaging/labels to prevent inbound chaos.

-

4) Receiving & quarantine:

book into a controlled location so stock doesn’t “accidentally” become available.

-

5) Inspection:

QC checks, photos, measurement, failure mode classification, and pass/fail decision.

-

6) Disposition:

restock / repair / scrap / supplier return / replacement shipment.

-

7) Financial settlement:

credit note (full/partial), chargeback to supplier, and cost attribution.

-

8) Root-cause loop:

tag recurring causes and link actions to prevent repeats (not just close tickets).

The Data You Must Capture (So Cases Don’t Turn into Arguments)

A returns and claims system wins on evidence + traceability.

If you can’t prove what happened, you end up negotiating outcomes case-by-case.

Minimum viable “RMA Case” record

- Customer, site, contact, account hierarchy

- Original document link (order / delivery / invoice)

- Item, variant, quantity, UoM

- Serial/lot/batch + production date

- Reason code + free-text symptom

- Evidence (photos, test results, documents)

- Requested outcome (credit / replace / repair)

- SLA owner, approvals, audit trail, timestamps

Reason Codes That Work in the Real World

Keep reason codes actionable. Your goal is not “categorisation”—it’s downstream decisions:

can we restock, should we scrap, do we chargeback, and what must be fixed upstream?

| Reason code |

Best used when |

Typical disposition |

| Transit damage |

Packaging damage or courier handling issue |

Replace + logistics claim / carrier evidence |

| Spec deviation |

Measured out-of-tolerance / quality failure |

Quarantine + QC decision + CAPA |

| Wrong item shipped |

Pick/pack or labelling mismatch |

Return to stock + reship correct item |

| No fault found |

Item passes inspection; usage/setup error |

Return to stock + advisory note |

| Warranty failure |

Within warranty period, documented symptom |

Repair/replace + trend analysis |

Disposition Rules: Where Cost Control Actually Happens

Without disposition rules, your business defaults to the most expensive decision: replacing everything “just in case”.

A robust workflow defines decision logic based on condition, warranty, and traceability.

Return to stock

Only if inspection passes and packaging/traceability criteria are met. Book it into the correct location

and keep the audit trail.

Repair / rework

Route to a repair work order with parts usage tracking and labour costing, so margin impact is visible.

Scrap

Scrap should never be “a warehouse decision”. Require approval thresholds and attach evidence.

Supplier return / chargeback

If the root cause is upstream, link the claim to supplier lots, inbound QC, and purchase terms.

Finance Handling: Credit Notes Without Disputes

Claims often collapse at the “money step”. The fix is simple: the credit decision must be tied to

inspection outcomes, not inbox pressure.

Practical settlement rules

- Issue “provisional approval” for inbound only—final credit after inspection.

- Support partial credits by linking quantity + condition to the claim line items.

- Track freight responsibility explicitly (customer / supplier / your organisation).

- Attribute cost (scrap, rework, replacement) to product/lot to reveal trends.

Root-Cause Tracking: Turn Claims into Operational Improvement

Closing a claim is not the same as solving a problem. The workflow should create a lightweight loop:

symptom → failure mode → suspected cause → verified cause → corrective action.

Structured methods (e.g., 5 Whys, fishbone, 8D-style problem solving) work best when the system forces consistency.

What to link for repeat-prevention

Cause taxonomy: process, supplier, design, packaging, handling, usage.

Corrective action: owner, due date, verification evidence, effectiveness check.

Impact analysis: affected lots, customers, and risk of recurrence.

KPIs That Actually Matter (And Drive Behaviour)

If you only measure “number of claims”, teams will game it. Measure the economics and the repeat rate instead.

- Cycle time: intake → authorisation → receipt → closure

- Cost per case: freight + labour + scrap + replacement

- Repeat rate: recurring causes by product/lot/supplier

- No fault found ratio: signals education, documentation, or misuse patterns

- Chargeback recovery: recovered cost vs eligible cost

A Practical Implementation Plan (30 / 60 / 90 Days)

First 30 days: control the intake

- Define reason codes, evidence rules, and eligibility gates

- Implement RMA numbering + ownership + SLA timestamps

- Quarantine location logic for returned inventory

60 days: connect decisions to inventory and finance

- Inspection outcomes drive disposition automatically

- Credit notes tied to claim line items (partial credits supported)

- Supplier return/chargeback data captured consistently

90 days: build the improvement loop

- Root-cause tagging + corrective action tracking

- Trend dashboards by product, lot, supplier, customer segment

- Process playbooks for repeat scenarios (damage, wrong item, warranty)

FAQ

Should we issue credit before the return arrives?

In most cases, no. Use provisional approval for inbound logistics, then issue final credit after inspection.

This protects margin and prevents repeat disputes.

How do we stop warehouse “leakage” back into sellable stock?

Quarantine returns into a controlled location and require an inspection status before any movement to available inventory.

The system must enforce this—not policy documents.

What’s the fastest way to reduce claim volume?

Start with reason code consistency and evidence requirements. You’ll quickly see whether the top drivers are

packaging, picking/packing, supplier lots, or usage/setup patterns.

Want an audit-ready returns and claims workflow for your operation?

If you’re running manufacturing or wholesale processes, I can map your current claims reality into a clean RMA workflow:

gated intake, inspection-driven disposition, credit handling, and root-cause visibility.

Typical response time: within 24 hours • Clear scope & timeline • Documentation included