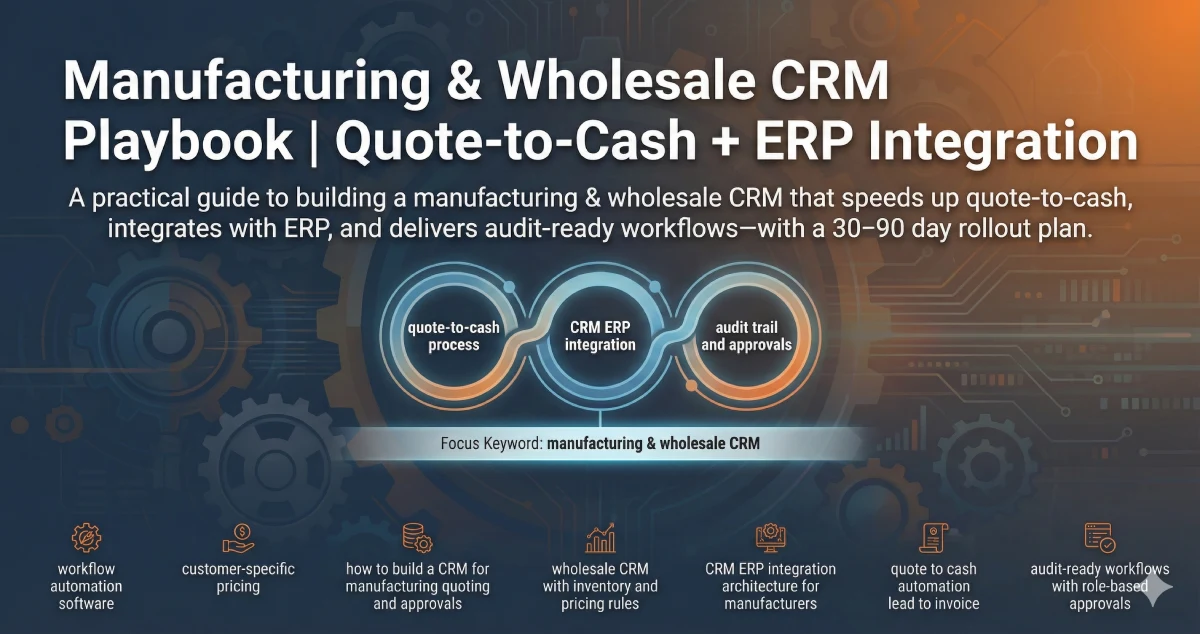

Why this matters in manufacturing & wholesale

In manufacturing and wholesale, revenue speed is tied to operational precision. If your CRM can’t reflect

real constraints (credit risk, stock signals, lead times, pricing rules), sales becomes guesswork—

and operations pays the price.

Typical symptoms

- Quotes take days because approvals and pricing logic are manual.

- Sales promises delivery dates without visibility into constraints.

- Customer history is fragmented (emails, spreadsheets, messaging apps).

- Order changes and exceptions are not traceable—leading to disputes.

Executive takeaway

The objective is not “a new CRM.” The objective is a single operating model:

one pipeline, one quote process, one approval path, one source of truth.

What a “good” Manufacturing & Wholesale CRM actually includes

A manufacturing and wholesale CRM is not a generic contact database. It is a sales execution layer that

understands quoting realities, commercial constraints, and operational signals.

Core capabilities (non-negotiable)

- Account & contact model: multi-site accounts, buying roles, payment terms, credit flags.

- Pipeline governance: defined stages, SLAs, activity tracking, deal hygiene rules.

- Quoting engine: price lists, margin controls, discounts, validity periods, revisions.

- Approvals: thresholds, escalation paths, audit trail for who approved what and why.

- Order handoff: quote → order handover with validations and structured notes.

- Reporting: forecast, win/loss, cycle time, margin, conversion by segment.

Supporting capabilities that create leverage

- Task & follow-up automation tied to pipeline stage changes.

- Customer comms timeline (emails/notes/calls) with a consistent structure.

- Document management for contracts, specs, POs, and quote PDFs.

Workflow blueprint: quote-to-cash (without chaos)

A high-performing workflow is predictable. Everyone knows the next step, required inputs, and the owner.

Below is a practical quote-to-cash skeleton you can implement in phases.

Stage 1: Lead qualification

- Define qualification criteria (ICP fit, urgency, budget, decision maker availability).

- Capture commercial constraints early (terms, shipping region, minimum order, product fit).

Stage 2: Quote creation

- Standardise line items, units, and pricing sources.

- Enforce margin guardrails with exception paths.

- Track quote versions and reasons for change.

Stage 3: Approvals

- Approval thresholds by discount/margin/credit risk.

- Structured justification fields to protect governance.

- Audit-ready history for decision accountability.

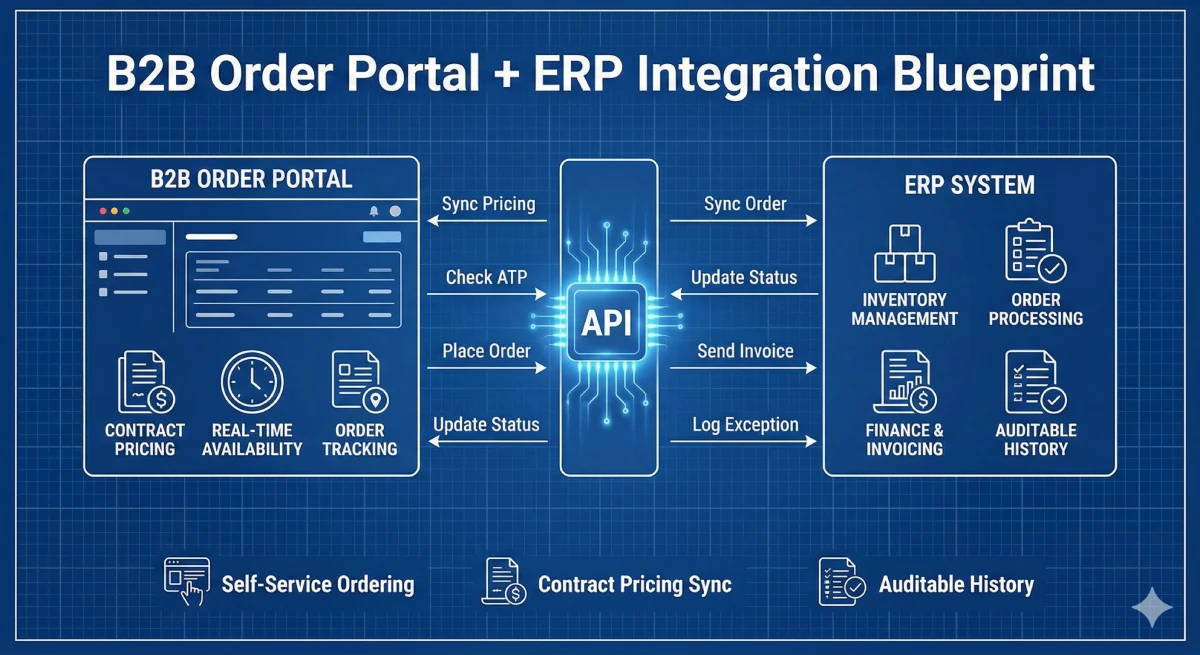

Stage 4: Order handover

- Validate customer terms, addresses, tax fields, and required documents.

- Convert quote to order with immutable snapshots where needed.

- Push structured data to downstream systems via stable integration contracts.

Practical KPI set (start here)

- Quote cycle time (median + 90th percentile)

- Approval latency (by threshold)

- Win rate by segment

- Gross margin by product family

- Quote revision count per deal

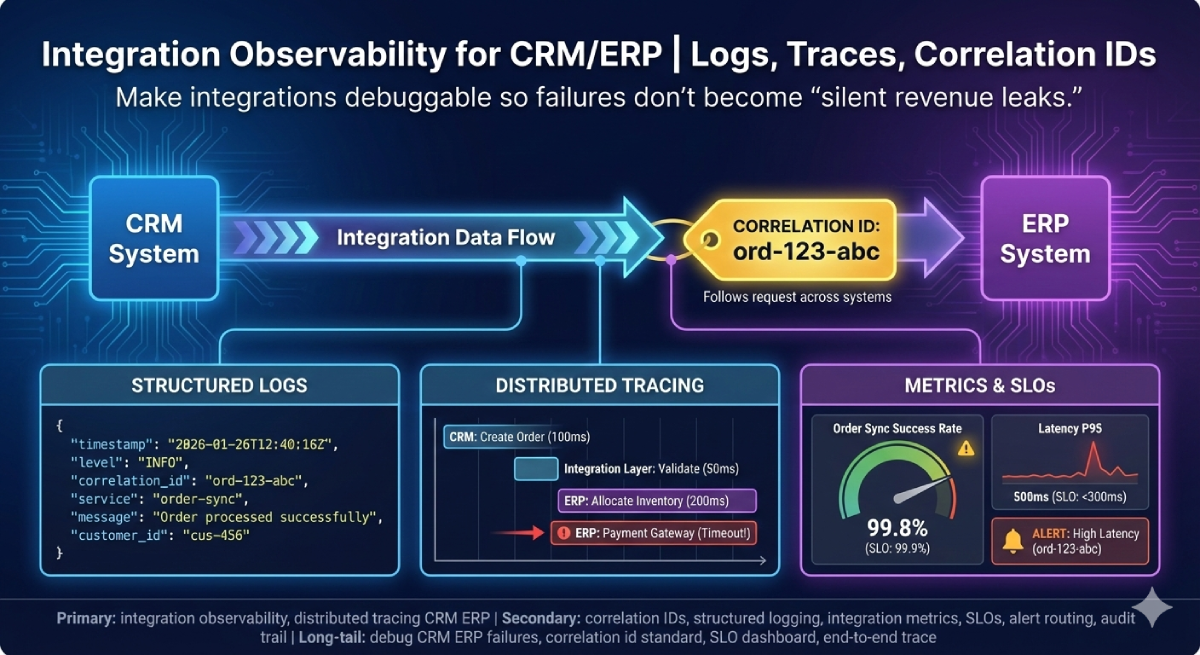

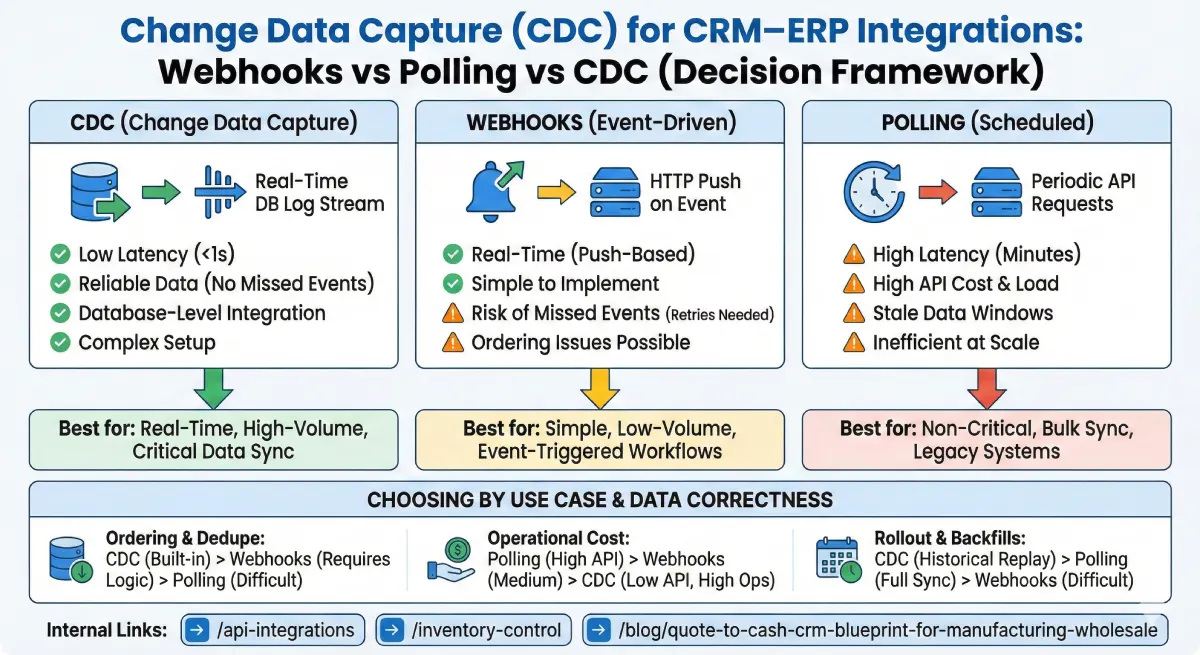

Integration strategy: keep it reliable

Most organisations fail at integrations because they treat them as “quick connections” instead of

governed interfaces. The goal is to make changes safe and predictable.

What to integrate first

- Customer master data: accounts, terms, tax identifiers.

- Product/pricing signals: price lists, discount rules, lead times.

- Order/invoice references: statuses, payment state, credit blocks.

Governance rules that prevent future pain

- Version your API contracts for safe evolution.

- Log every request with correlation IDs for traceability.

- Define error standards (human-readable + machine-parseable).

- Use idempotency for create operations (avoid duplicates).

30–90 day rollout plan (realistic delivery)

Weeks 1–2: Foundation

- Map the quote-to-cash workflow and define acceptance criteria.

- Implement pipeline stages, accounts, and activity tracking.

- Decide data ownership and integration boundaries.

Weeks 3–6: Quoting + approvals

- Build quoting with price sources and margin controls.

- Add approvals with thresholds and audit trail.

- Roll out reporting for cycle time and conversion.

Weeks 7–12: Integrations + operational hardening

- Integrate master data and status signals.

- Introduce validation, error handling, and alerts.

- Optimise performance for daily operational use.

Common mistakes (and how to avoid them)

- Building screens before workflow: start with process and required data.

- No ownership model: decide where truth lives (CRM vs back office).

- Uncontrolled custom fields: enforce governance to prevent schema sprawl.

- Integrations without monitoring: add logs, alerts, and replay strategies.

FAQ

How is a manufacturing and wholesale CRM different from a generic CRM?

It includes quote governance, approvals, pricing rules, operational constraints, and integration patterns

designed for order-driven businesses—not just contact tracking.

What should we implement first: CRM screens or integrations?

Start with workflow and required data contracts. Build minimum viable screens that enforce the process,

then integrate the highest-value signals (terms, pricing, status) with monitoring.

How do we avoid data duplication across tools?

Define ownership boundaries (source of truth), establish unique identifiers, use idempotency for creates,

and implement change logs with clear sync rules.

Want a practical roadmap for your CRM and integrations?

Share a short summary of your quote-to-cash flow and current tools. You’ll get a structured plan with milestones,

risks, and integration boundaries—aligned to how manufacturing and wholesale teams actually operate.